BDR430 Brushless Motor Electric Drive

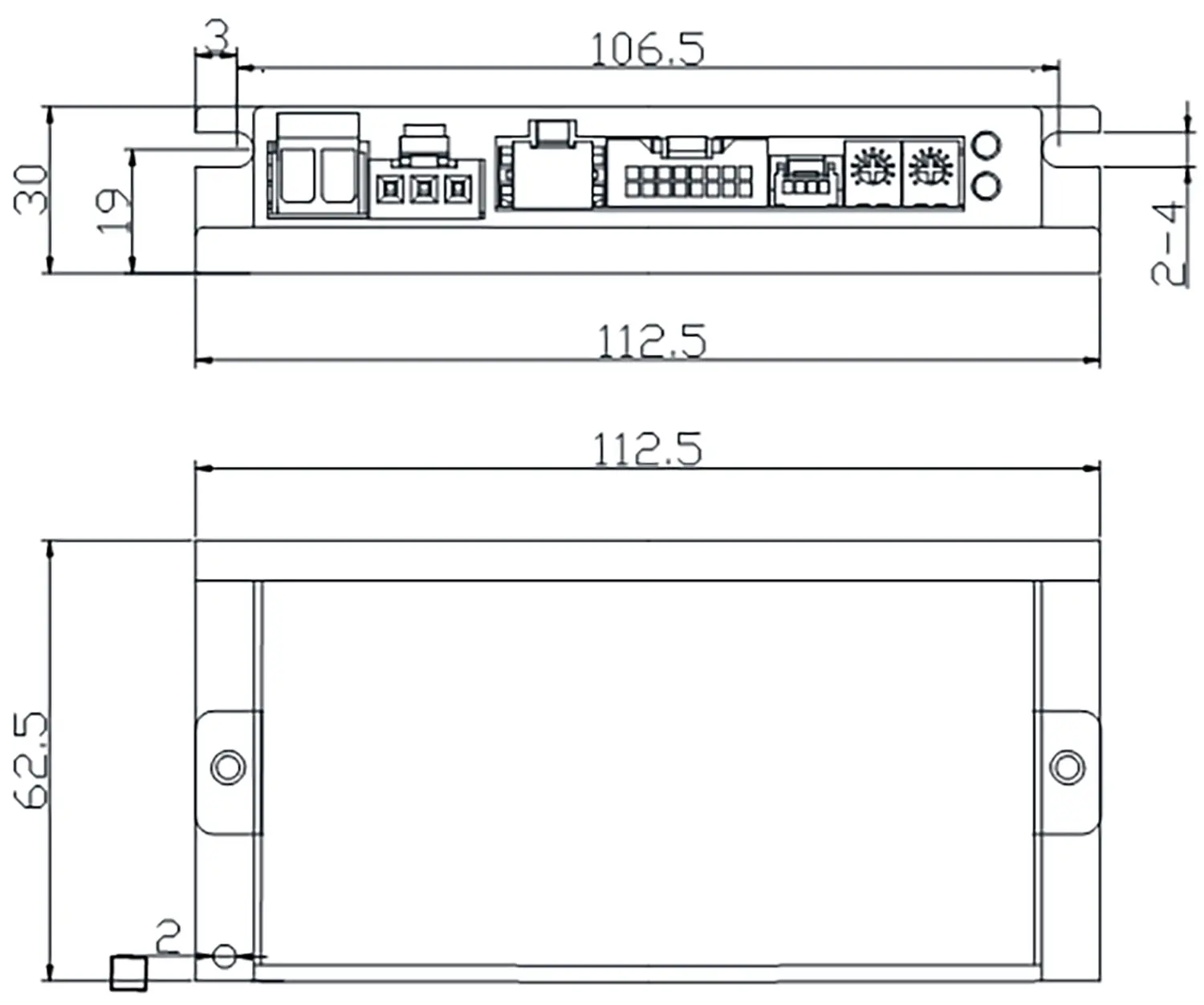

The BDR430 motor driver stands out for its compact design and versatile functionality, making it an ideal solution for a range of applications that require precise motor control. Measuring just 113mm by 63mm by 30mm, this small and lightweight device is easy to install and operate, even in space-constrained environments.

One of the key features of the BDR430 is its low-voltage operation at DC24V, ensuring safety and ease of use in various industrial settings. This low voltage requirement minimizes the risk of electrical hazards, making it a safer choice for operators and technicians.

The BDR430 is equipped with a rich set of interfaces that enhance its functionality and compatibility. It includes eight digital input ports, two digital output ports, one analog input port, and a 5V auxiliary power output, allowing it to interface seamlessly with a wide range of sensors, controllers, and other peripheral devices. This versatility makes it suitable for integration into complex automation systems.

Moreover, the BDR430 supports multiple speed control methods, including external analog signals, internal analog signals, IO control, and Modbus RTU communication. This flexibility allows users to choose the most suitable control method for their specific application, whether it involves simple manual adjustments or complex automated processes.

The driver also features bi-directional isolated IO, making it compatible with both European and Japanese PLC input and output ports. This broad compatibility ensures that the BDR430 can be easily integrated into existing systems without requiring significant modifications or additional components.

Another standout feature of the BDR430 is its adaptive Hall sensor learning function, which allows it to adapt to various Hall sensor sequences in brushless motors. This capability ensures optimal performance across different motor types, enhancing the driver's versatility and usability.

In summary, the BDR430 motor driver is a powerful, compact, and highly adaptable solution designed to meet the needs of modern automation and motor control applications. Its combination of safety, versatility, and advanced features makes it a valuable addition to any industrial setup, ensuring precise and reliable motor operation across a wide range of scenarios.

| Parameter type | Numerical value unit |

| Supply voltage | 24VDC |

| Input current | 1.8A |

| Output power | 30W |

| Speed range | 120~2500rpm |

| Rate of velocity variation | ±1% |

| Speed regulation mode | Analog speed regulation, IO speed regulation, communication speed regulation |

| Number of input interfaces | 8 |

| Number of output interfaces | 2 |

| Speed output mode | Pulse, communication |

| Acceleration and deceleration can be adjusted | support |

| Multiple speed | Supports a maximum of 7 speed segments |

| Stopping moment maintenance | support |

| Current limitation | support |

| Motor positive direction setting | support |

| Data preservation | support |

| Protection function | Overcurrent, overload, overvoltage, undervoltage, phase failure, Hall fault, gridlock, overspeed |

| Fault indication | Digital display, alarm output |

Daniel.Ding

Daniel.Ding Ding

Ding