Revolutionizing Precision Automation: The Rise of XXY Alignment Platforms

As global industries continue to push the boundaries of automation, the demand for ultra-precise positioning and alignment technology has never been higher. At the forefront of this trend is the XXY alignment platform—a compact, highly accurate solution designed to meet the rigorous demands of semiconductor, electronics, PCB, and solar panel manufacturing.

The Evolution of Alignment Platforms

The concept of alignment platforms originated in Germany, where mechanical pin actuators were first used to align fixed and moving substrates in optical systems. Later, Japanese engineers advanced the design by integrating electrical actuation, giving birth to the early UVW (3-axis) alignment systems. Over time, the industry saw a shift toward more compact, modular, and efficient mechanisms—culminating in the XXY alignment platform.

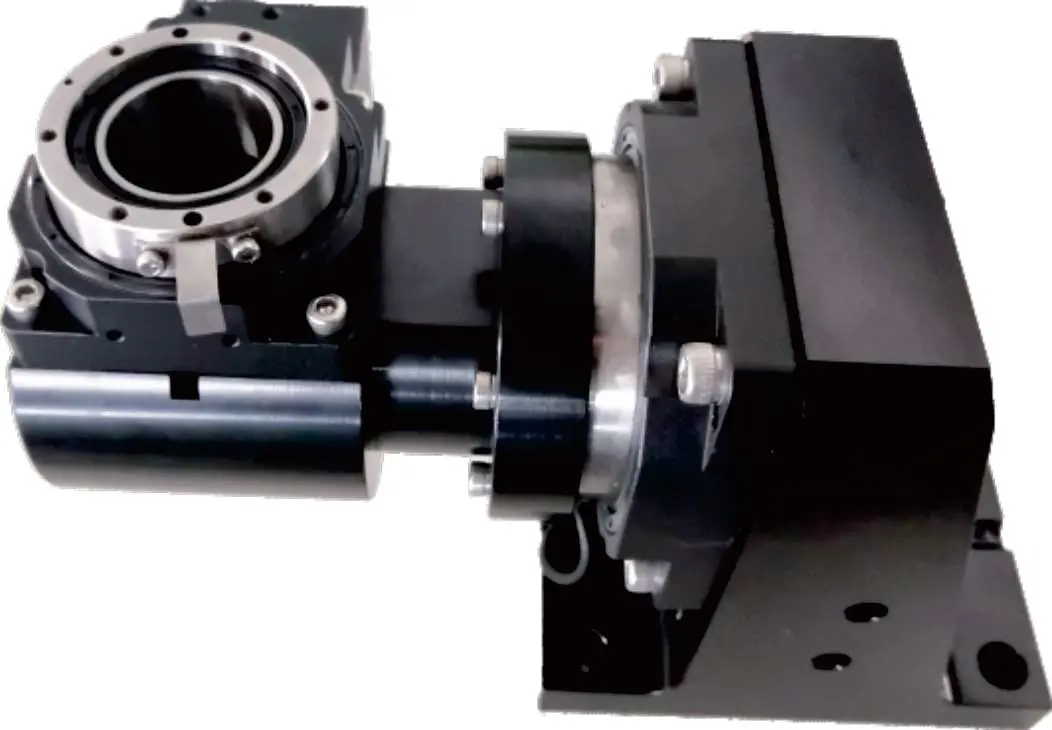

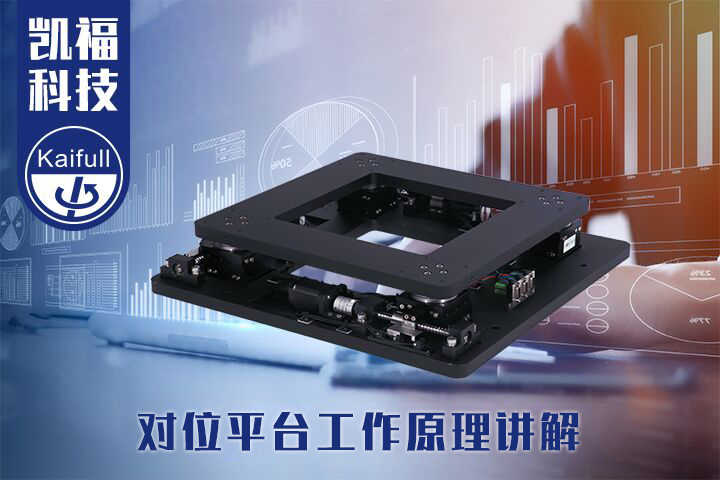

Unlike traditional XY platforms, the XXY structure offers a lower profile and a more integrated form factor. It combines two orthogonal translational axes and a rotational axis (θ) within a single mechanical assembly, ensuring synchronized and ultra-stable motion.

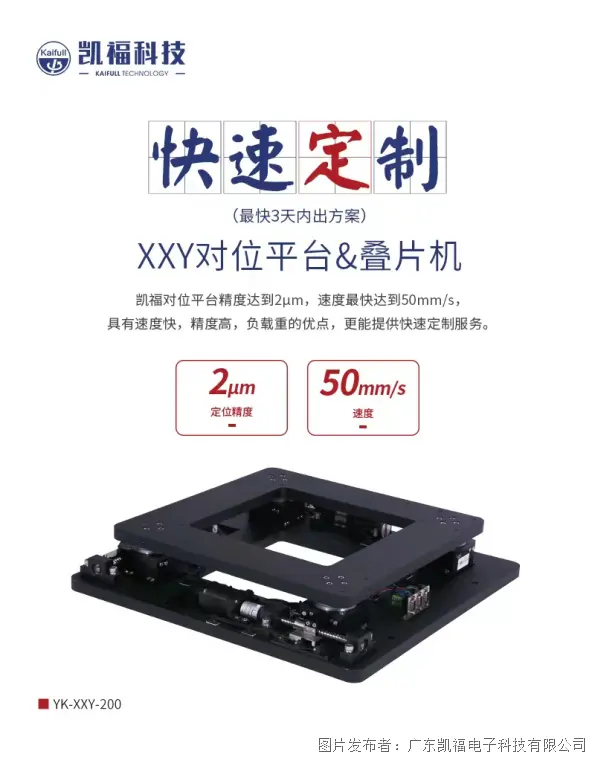

Kaifull: Driving Innovation from China

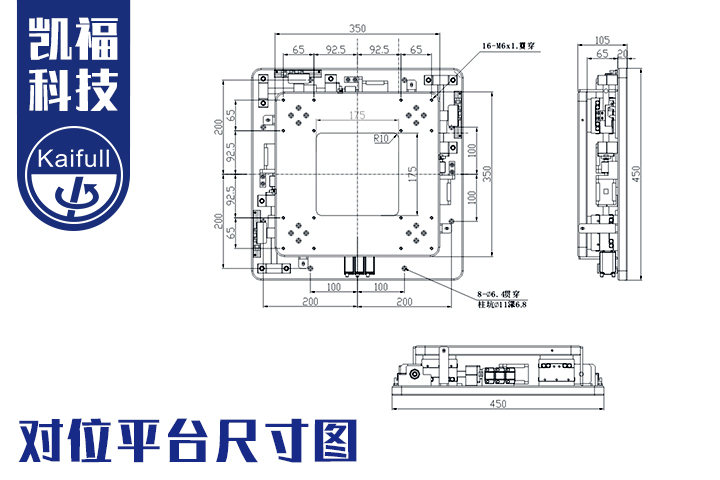

Established in 2008, Kaifull Electronic Technology (Guangdong) has become one of China’s leading developers of precision automation systems. Drawing from both Japanese engineering discipline and Taiwanese modular integration techniques, Kaifull has created a wide portfolio of customizable XXY alignment platforms. These platforms—also known as XYθ positioning stages or alignment correction modules—are increasingly adopted across China's high-tech manufacturing sector.

Kaifull design philosophy centers around compactness, accuracy, and reliability, making their platforms ideal for space-constrained environments requiring sub-micron repeatability.

Applications Across High-Tech Industries

The XXY alignment platform plays a crucial role in industries that demand micron-level precision and high throughput:

-

Semiconductor: Wafer inspection, dicing, chip packaging alignment

-

PCB: Exposure, screen printing, SMT pick-and-place, panel cutting

-

Display Technology: Alignment of LCD, LED, and OLED modules

-

Photovoltaics: Silver paste printing, laser scribing of solar panels

As Industrial Automation continues to expand, the XXY alignment platform is proving essential in replacing manual alignment processes that are prone to error and inefficiency.

Meeting the Future of Precision

Kaifull continues to invest in R&D to push the limits of motion control. With an in-house engineering team and international supply chain, the company is committed to providing scalable, custom solutions for customers worldwide. Whether for high-speed production lines or lab-level inspection systems, Kaifull’s XXY alignment platforms deliver the performance modern manufacturing demands.

About Kaifull

Kaifull Electronic Technology (Guangdong) specializes in motion control and precision automation equipment. With a focus on innovation and global competitiveness, the company serves clients in semiconductors, electronics, and new energy sectors.

Daniel.Ding

Daniel.Ding Ding

Ding