Kaifull Introduces New High-Torque Stepper Motor Series Amid Rapid Market Growth

June 2025, Guangdong Kaifull Electronic Technology Co., Ltd.

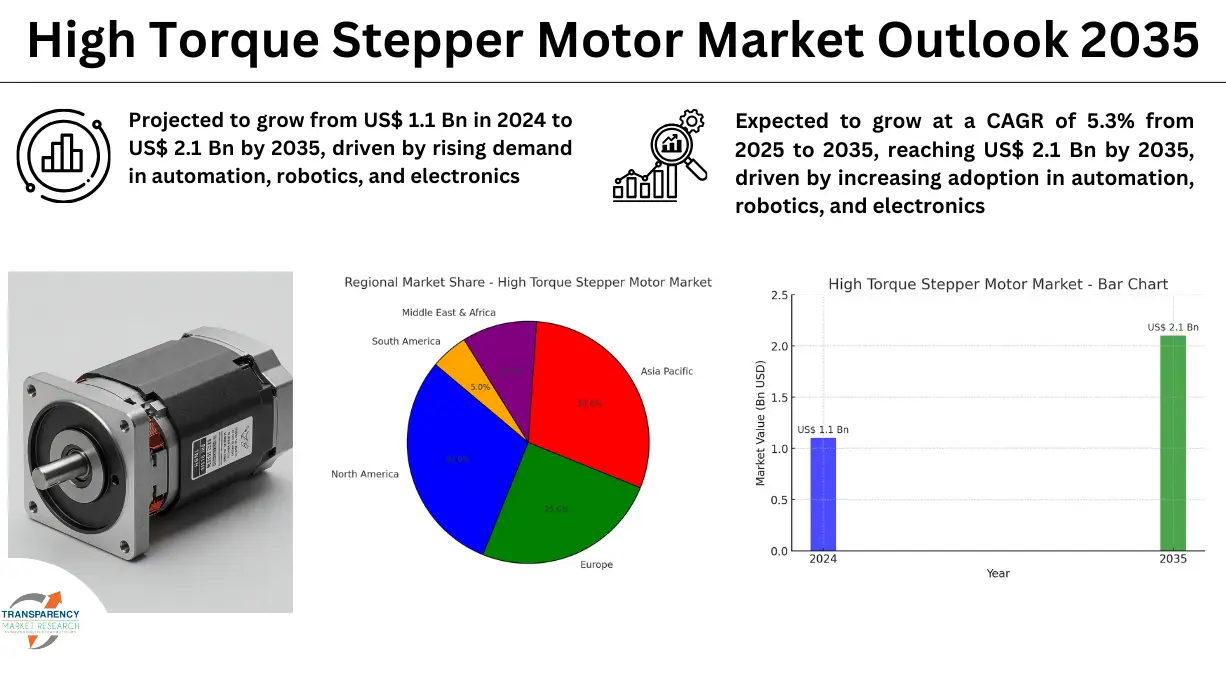

Kaifull today announced the launch of its latest high-torque Hybrid Stepper Motor series, designed to meet booming demand in robotics, automation, medical devices, and aerospace industries. This announcement comes as a recent Transparency Market Research report projects the global high-torque stepper motor market will grow from US $1.1 billion in 2024 to $2.1 billion by 2035, at a CAGR of 5.3%.

Rising Market Demand for High-Torque Solutions

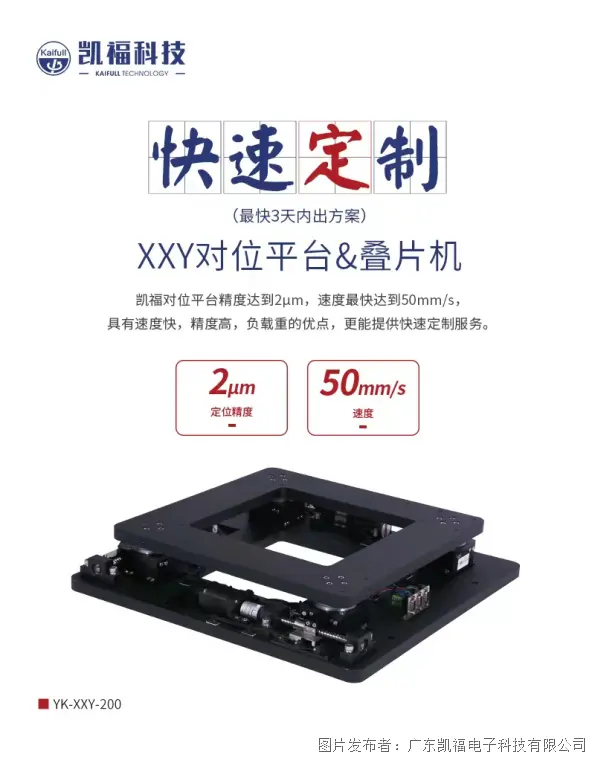

As manufacturers push for greater machine speed, accuracy, and load capacity, high-torque stepper motors have become critical components. Industries such as automated guided vehicles (AGVs), pick-and-place robots, and heavy-load 3D printers increasingly require motors that deliver sustained torque under demanding conditions. Kaifull’s new series addresses these needs by providing exceptional performance in compact form factors.

Key Features of Kaifull High-Torque Series

-

Superior Torque Density

-

Model Range: Available in NEMA sizes 23, 34, and 42.

-

Holding Torque: Up to 8 Nm in a 42 frame size, enabling direct drive of loads previously handled only by larger servo motors.

-

-

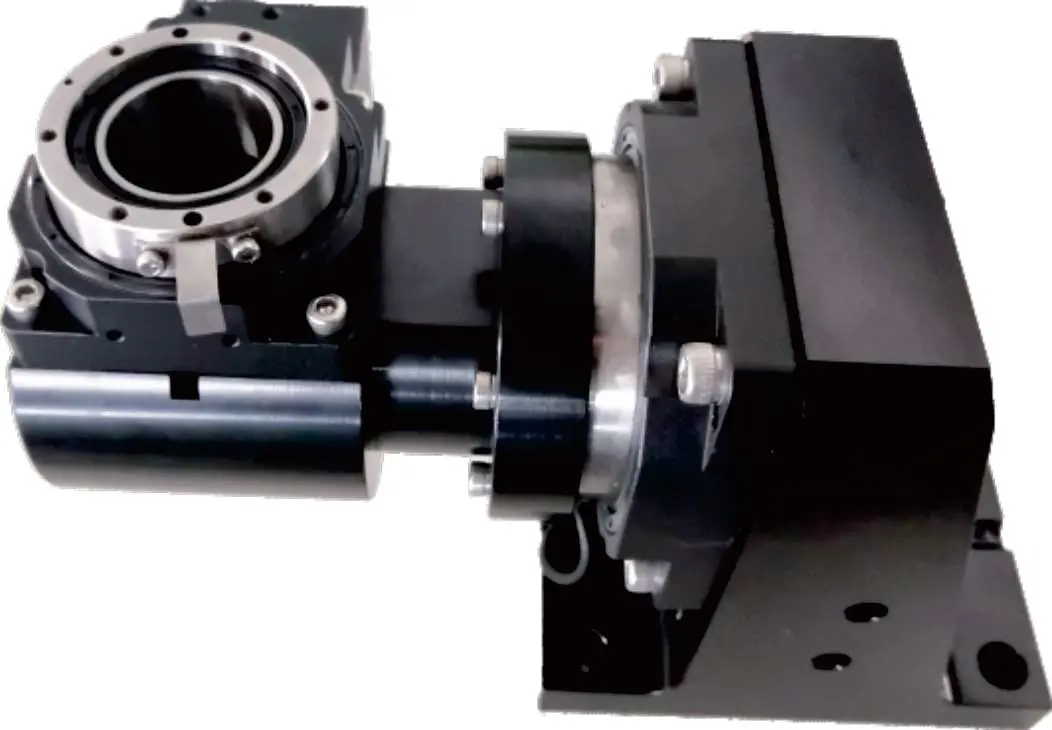

Advanced Hybrid Design

-

Rotor Construction: Multi-toothed iron core with concentric permanent magnets for enhanced magnetic flux guidance.

-

Precision Step Angle: 1.8° standard; optional 0.9° microstepping for ultra-fine positioning.

-

-

Optimized Thermal Management

-

High-Class Copper Windings: Cold-rolled sheet construction and enhanced heat-dissipation pathways reduce winding temperature by up to 20%.

-

Low-Heating Operation: Continuous-duty ratings at up to 1000 RPM ensure reliable performance in long-run applications.

-

-

Smooth, Oscillation-Free Performance

-

Internal Damping: Integrated damping elements eliminate mid-range resonances without external accessories.

-

Microstepping Drivers: Paired with Kaifull’s KDR-X series drivers for sinusoidal current control, resulting in near-silent operation and minimal vibration.

-

-

Easy System Integration

-

Modbus and EtherCAT Support: Enables closed-loop control and real-time monitoring of torque and position.

-

Standardized Mounting: NEMA-compliant flanges and threaded shaft ends simplify mechanical assembly.

-

Applications Across Industries

-

Robotics & AGVs: High starting torque and compact size make the motors ideal for mobile robots carrying payloads up to 200 kg.

-

CNC and Machine Tools: Precise, backlash-free motion enhances surface finish quality in milling and engraving.

-

Medical Devices: Robust torque supports syringe pumps and imaging tables that demand smooth, reliable actuation.

-

Aerospace & Defense: Motors withstand extreme temperatures and shock, suitable for UAV gimbals and satellite deployment mechanisms.

Kaifull Commitment to Innovation

“High-torque stepper motors are essential for the next generation of automation,” said Dr. Li Wei, CTO of Kaifull. “Our new series combines cutting-edge magnetic design, superior thermal performance, and seamless control integration to empower OEMs and system integrators worldwide.”

For more information, visit Best stepper motor Suppliers, Factory | Kaifull.

Daniel.Ding

Daniel.Ding Ding

Ding